Helium Leak Test for Cryogen Tanks

Test device for

cryogen tanks

For the reliable testing of cryogen tanks

Alternatives for combustion engines

Electric mobility will be gaining more and more impact in the automotive market, while the use of combustion engine driven vehicles will decrease.

Hybrid and battery supported drives will be the preferred solution in the near future for passenger vehicles, but fuel cells and the use of hydrogen as a fuel will become more important. Particularly for commercial and heavy duty vehicles as well as the public transport sector and the aviation industry fuel cell drives are a real alternative to combustion engines.

Short re-fueling times and a sufficient range are the main advantages of this concept. If the hydrogen is produced by using regenerative energies (e.g. solar or wind turbines), even the ecological balance is positive – keyword green hydrogen.

Cryogen tanks as storage for liquid Hydrogen

Besides storing hydrogen gas under high pressure, it is also possible to store liquid hydrogen at lower pressures in cryogen tanks. The quality of the heat insulation of the tank is very important, as the boiling point of liquid hydrogen is approximately -253°C. Liquid hydrogen transitions to gas at higher temperatures and requires then much more volume.

Cryogen tanks are used to store liquid hydrogen over a sufficient period of time. These tanks consist of the literal fuel tank which is assembled into a second container.

The fuel tank has an aluminum fabric on the outside, which protects the inner volume from heat emissions. Additionally, there is a high vacuum in the volume between the outer container and the fuel tank, in order to minimize the heat impact from the environment on the liquid hydrogen.

In ideal circumstances it is possible to store liquid hydrogen over a few days. A precondition is that both the hydrogen fuel tank and the outer container have a very low leak rate. To ensure this the system is checked in a helium leak test device before use.

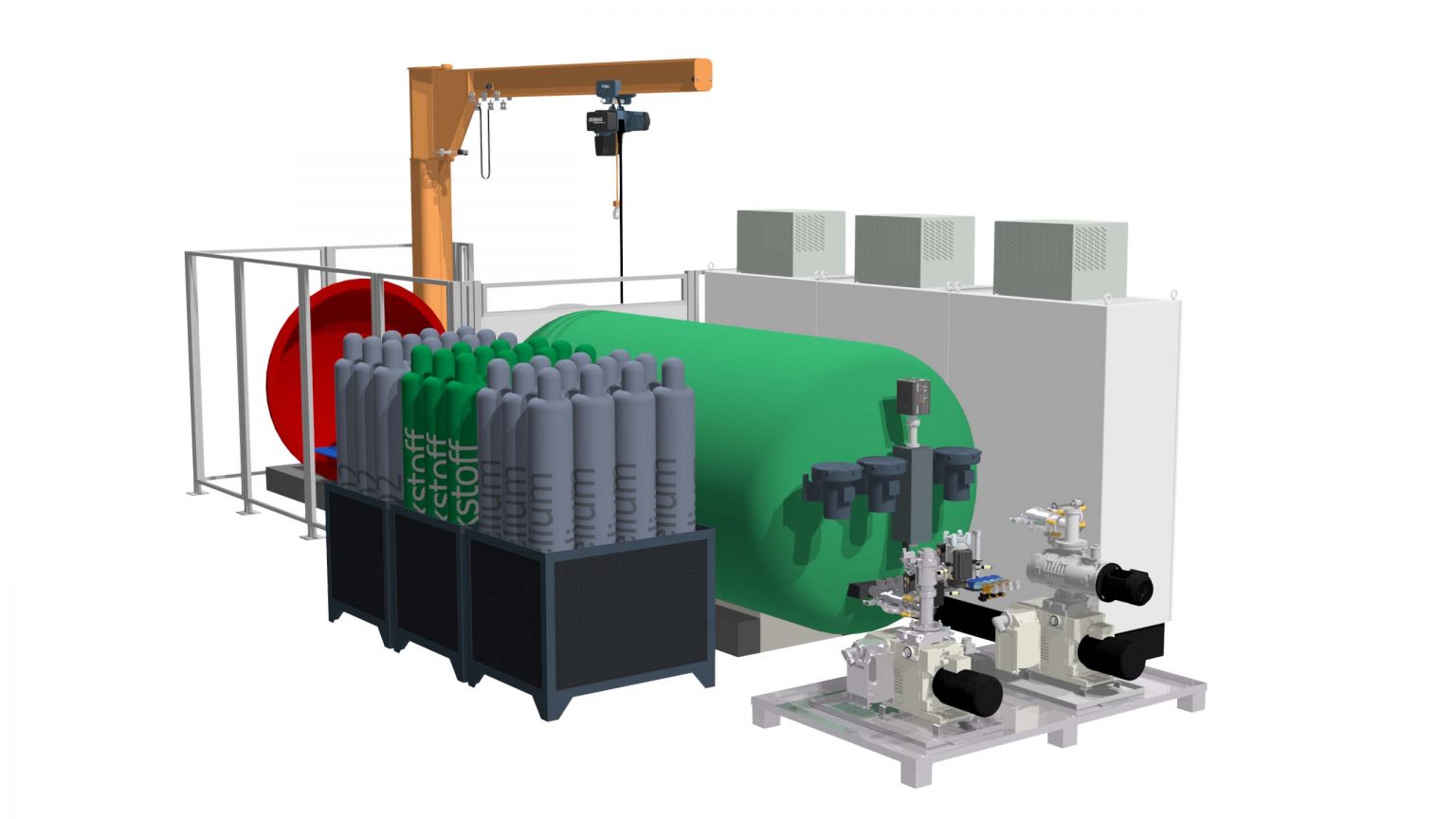

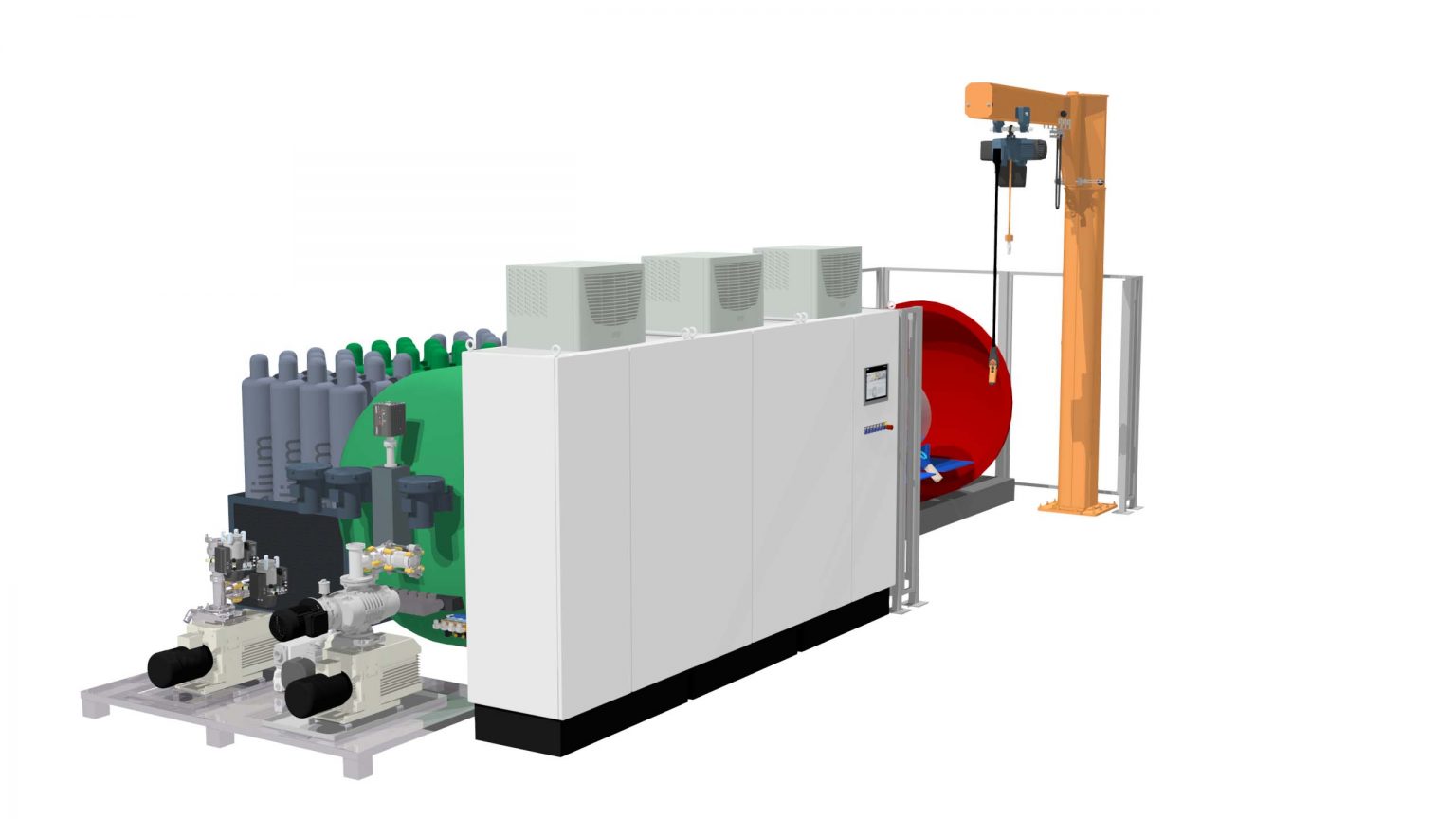

Test device for cryogen tanks

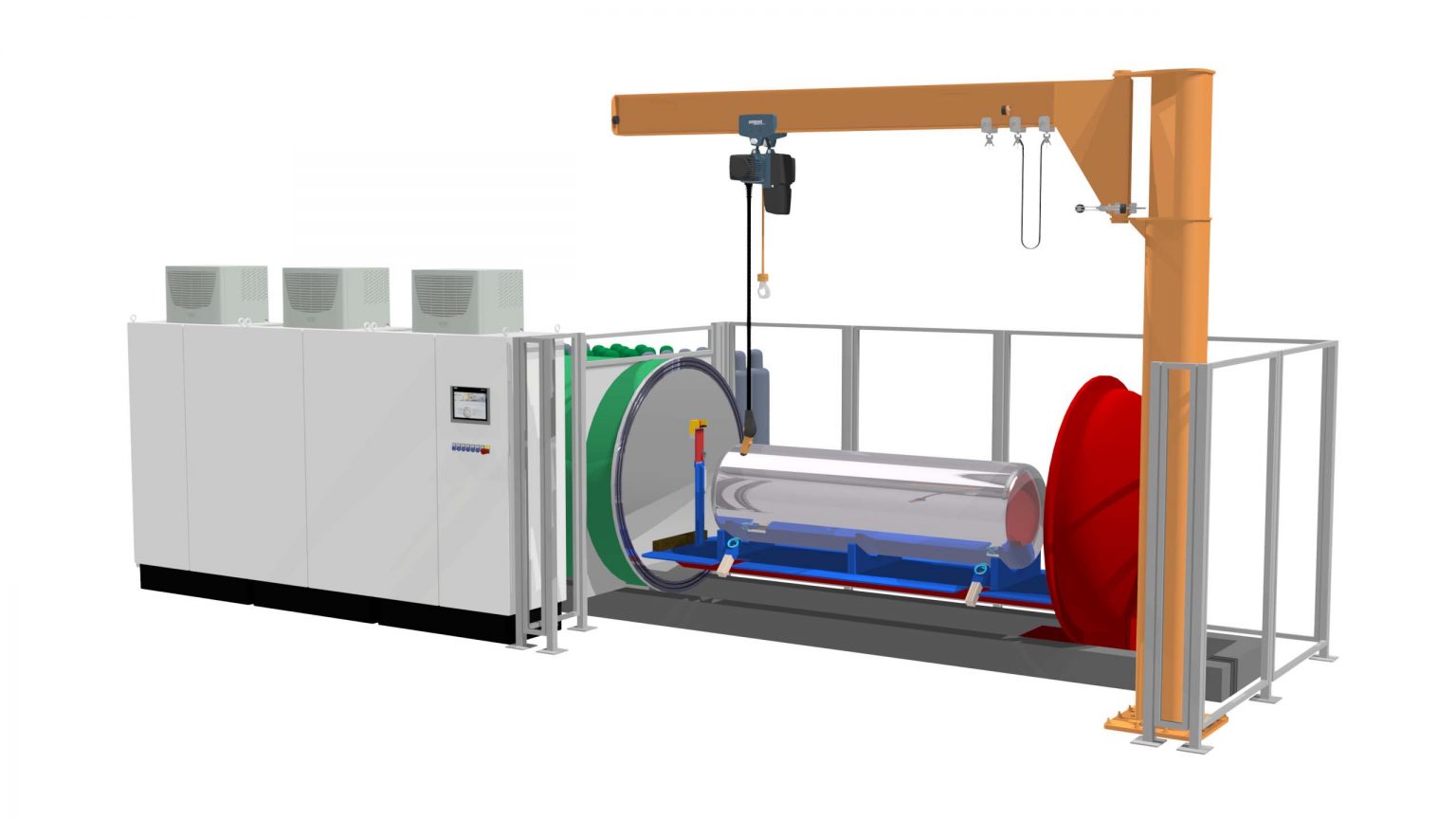

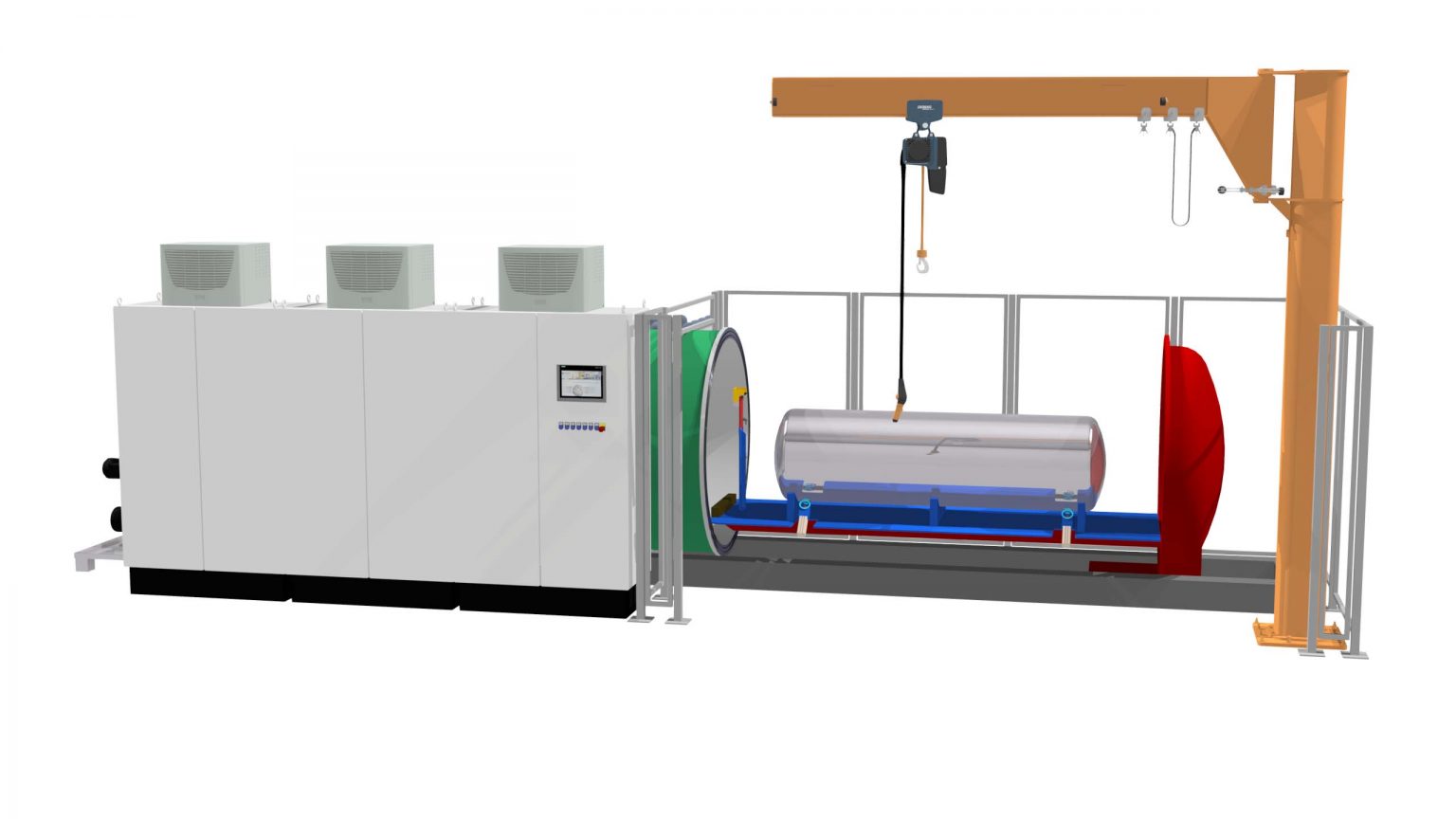

During the development it is often also important to gather some insights to the evacuation behaviour of a cryogen tank. With our newly developed test device for cryogen tanks, it is possible to leak test tanks as well as making tests to check the evacuation behaviour.

The device is equipped with the following features:

- Helium vacuum leak test ≤ 1,0 ⋅ 10−6 mbar ⋅ l/s

- Gas supply for two different gases (e.g. nitrogen and helium) with the related valves to purge the different containers

- High-end vacuum pumps to evacuate the insulation volume to ≤ 1,0 ⋅ 10−7mbar

- Specific vacuum closing valves to securely close the evacuated insulation volume

- Heating device (up to 150°C) and gas circulation devices for

- … the test chamber

- … the part

- Flexible programable data/function blocks for the equipment control, to realize different processes and test procedures

- Display of process data and data interface to acquisition software

The test chamber has a sufficient size for test parts of 800 × 800 × 3.000 mm (W × H × L). The device is equipped with a lift assist for easy loading and unloading of parts. After loading the part, the part fixture is pushed into the test chamber on a linear rail system and the connections of the supply units to the test parts are made automatically inside of the chamber. The test can start as soon as the test chamber has been closed.

Service laboratory testing / prototype device

Besides the purchasing your own device, we offer our customers also to use a test device at our head quarter in Barßel, Germany, to perform prototype test or small test series. Particularly during the prototype phase this is an economic way, to gain first insights, which can be used for the further developments and improvements of a product.

We would be pleased to give you more details about this equipment in a personal conversation. We are looking forward to your request.

Contact us for more information

Daniel Schönbohm

Managing Director MACEAS